Founded in 2010, QH-PACK has grown from a small workshop into a modern enterprise with a 30,000 m² production facility, driven by our pursuit of excellence in machinery manufacturing and our commitment to serving customers. The company currently employs 50 staff members, with an annual output value of approximately RMB 200 million. QH-PACK specializes in manufacturing carton packaging equipment and has developed into a modern production enterprise.

QH-PACK has an independent R&D team and has obtained multiple utility model patents. The cardboard manufacturing equipment is certified under ISO9001 Quality Management System and CE certification.

Looking ahead, QH-PACK remains committed to the business philosophy of “quality first, reputation foremost”. The enterprise holds the spirit of innovation, continuous improvement, strict management, and excellence, while maintaining a people-oriented approach and a customer-first strategy.

The company offers a complete range of corrugated board manufacturing equipment, recognized by customers for timely delivery and thoughtful service. In the future, the enterprise will continue to be market-oriented and technology-driven, constantly upgrading the equipment, improving product quality, enhancing after-sales service, and contributing to the society.

Various dimensional and quality inspections are conducted on all purchased components upon their arrival.

The professionals collaborate according to the assembly drawings to build the machines and complete the electrical installation. Every screw is tightened carefully, with strong attention to detail.

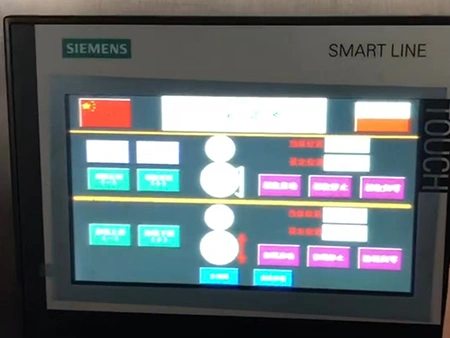

The operator is testing the slotter of the printing machine. After entering the carton length, width, and height on the control panel, the slotting knives automatically move into position. The operator only needs to check whether the knives align accurately with the designated scale marks.

The operator is testing the rotary die-cutter of the printing machine. By entering the phase settings on the control panel, the die-cutting roller automatically rotates to the correct position. Once the machine is started, producing the desired carton shape means the adjustment is successful.