5-Ply Corrugated Cardboard Production Line

Request a Quote

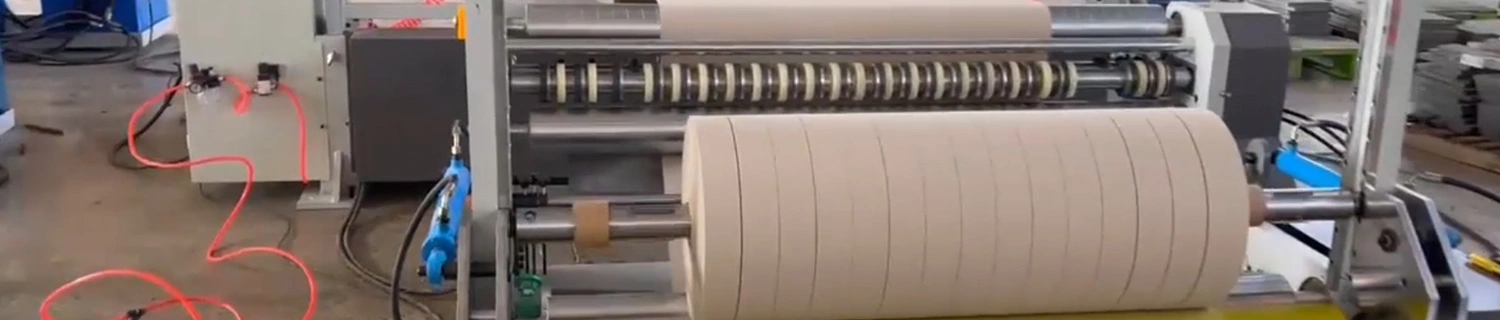

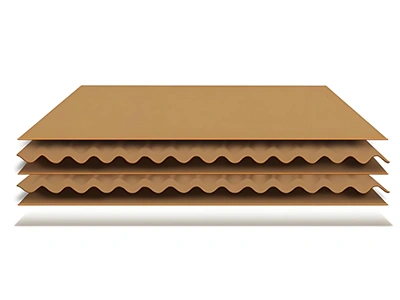

The 5-ply corrugated cardboard production line is an automated system for manufacturing 5-ply corrugated board. Its core function is to process five layers of corrugated paper through fluting, gluing, and laminating. 5-ply corrugated board is primarily used in the packaging sector and is suitable for industries such as food, home appliances, and daily chemicals.

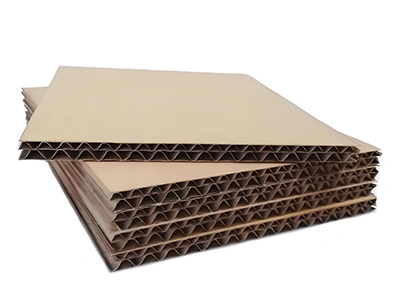

Sample Display

Technical Specifications

| Effective width, mm | 1400-2500 | |

| Designed production speed, m/min | 100-300 | |

| 5-ply line operating speed, m/min | 60-200 | |

| Max. single-change speed, m/min | 40 | |

| Longitudinal separation accuracy, mm | ±1 | |

| Cross-cutting accuracy, mm | ±1 | |

| Operating conditions: At a production width of 1600mm, meeting the paper specifications below and ensuring the surface temperature of heated components is maintained at 175℃. | ||

| Linerboard specification | 100-180g/㎡, ring crush index ≥8N·m/g (moisture content 8-10%) | |

| Medium paper specification | 80-160g/㎡, ring crush index ≥5.5N·m/g (moisture content 8-10%) | |

| Corrugating medium specification | 90-160g/㎡, ring crush index ≥6N·m/g (moisture content 8-10%) | |

| Flute combinations | A, C, B, E, F, G | |

| Steam requirement | Max. pressure | 16kg/cm² |

| Typical pressure | 10-12kg/cm² | |

| Consumption | 4000kg/hr | |

| Power supply | AC380V 50Hz 3PH | |

| Installed capacity | Approx. 300kW | |

| Typical power consumption | Approx. 250kW | |

| Compressed air | Max. pressure | 9kg/cm² |

| Typical pressure | 4-8kg/cm² | |

| Consumption | 1m³/min | |

| Space requirement | Approx. Lmin65-85mxWmin6mxHmin5m (subject to drawings provided by the supplier and approved) | |

Equipment Composition