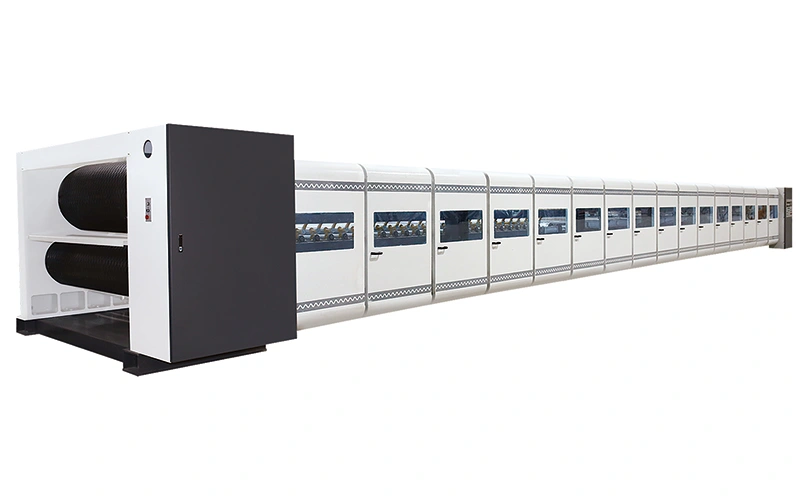

Double Facer Machine

Hot plate section for multi-ply corrugated board production through uniform heating and pressure bonding

Request a Quote

The double facer machine processes the laminated corrugated board semi-finished product through three main stages, thermal bonding, pressure smoothing, and cooling, to strengthen the board structure and stabilize the surface profile.

Features

- The heating plates are precision-ground to ensure uniform heat transfer and are arranged in multi-layer parallel groups.

- The conveyor belt system includes automatic tracking correction and dual tension mechanisms for stable operation with minimal manual adjustment.

- Both upper and lower cotton belts feature independent tensioning and fine-tuning systems to improve bonding quality and production accuracy.

- Drive rollers use a herringbone-pattern wear-resistant rubber surface and variable-frequency motor control, ensuring smooth conveying and flexible speed adjustment.

- The double facer supports customized configurations, including adjustable machine width and number of heating plates based on production capacity needs.

- Equipped with a pressure plate system to enhance the flatness and compactness of the finished corrugated board.

Technical Specifications

| Max. effective width, mm | 1400-2500 |

| Operating direction | Left or right (subject to customer factory layout) |

| Max. mechanical speed, m/min | 100-200 |

| Temperature requirement, ℃ | 160-200 |

| Steam pressure, MPa | 0.8-1.3 |

| Air supply pressure, MPa | 0.6-0.9 |

| Cooling & setting length, m | 4-6 |

| Number of heating plates | 10-22 |

| Hydraulic system pressure, MPa | 6-8 |