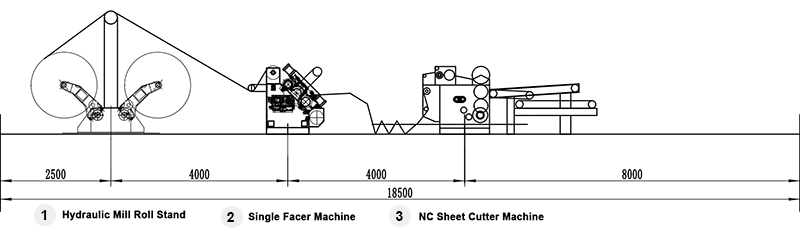

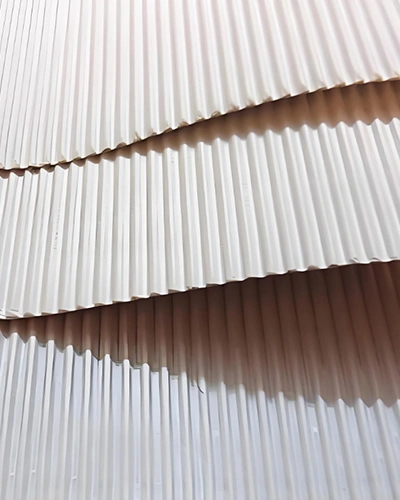

2-Ply Corrugated Cardboard Production Line

The 2-ply corrugated cardboard production line ss mainly used for producing single-face corrugated board. The equipment features high efficiency, a high degree of automation, and wide applicability, and is widely used in packaging cartons for food, beverages, pharmaceuticals, tobacco, and alcohol industries.

- Low production cost

- Easy to operate

- Small footprint

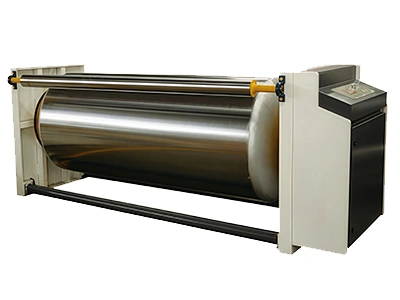

Hydraulic Mill Roll Stand

The hydraulic mill roll stand uses a hydraulic drive system to complete clamping, lifting, and lateral movement, enabling fully automated operation with high efficiency, reduced labor intensity, and flexible customization options.

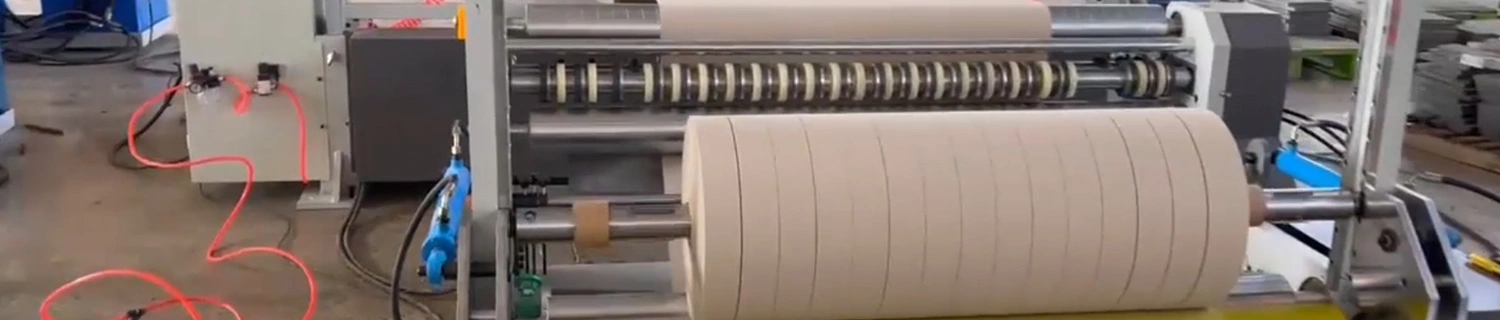

Single Facer Machine, Cassette Type

The cassette-type single facer machine forms corrugated fluting by pressing the corrugated medium into shape and laminating it with a liner to produce single-face corrugated board. The machine uses a negative-pressure design to ensure uniform flute formation and precise gluing.

NC Sheet Cutter Machine

NC sheet cutter machine is an automated board-cutting machine featuring customizable width, optional stacking function, and variable-frequency control. It is suitable for various production specifications and speeds. A stacking unit can be added as needed.

- High speed and high output

- Fully automatic computer intelligent control

- Simple HIM operation

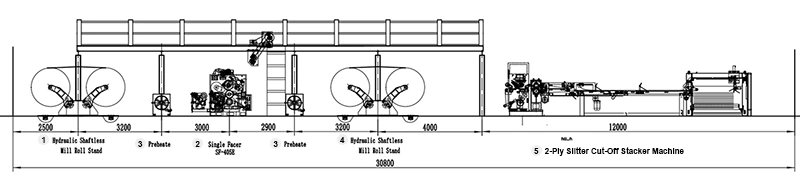

Hydraulic Mill Roll Stand

The hydraulic mill roll stand uses a hydraulic drive system to complete clamping, lifting, and lateral movement, enabling fully automated operation with high efficiency, reduced labor intensity, and flexible customization options.

Single Facer Machine, Cassette Type

The cassette-type single facer machine forms corrugated fluting by pressing the corrugated medium into shape and laminating it with a liner to produce single-face corrugated board. The machine uses a negative-pressure design to ensure uniform flute formation and precise gluing.

Pre-Heater Machine

The pre-heater machine uses angle-adjustable steam-heated cylinders to preheat the paper, ensuring proper moisture reduction and optimal bonding performance.

Corrugator Overhead Bridge

In the production of corrugated board, the overhead bridge (conveyor bridge) is mainly responsible for transporting and lifting the semi-finished corrugated paper, facilitating subsequent multi-layer lamination.

2-Ply Slitter Cut-Off Stacker Machine

The single-layer gluing machine is specialized equipment used in corrugated board production lines to apply an even layer of glue to one side of the board.

| Max. paper width, mm | 1450-2500 | |

| Designed production speed, m/min | 100-200 | |

| Economic speed, m/min | 50-150 | |

| Steam consumption, kg/hr | 500-1000 | |

| Operating conditions: At a production width of 1200-2500mm, meeting the paper specifications below and ensuring the surface temperature of heated components is maintained at 175℃. | ||

| Linerboard specification | 100-180g/㎡, ring crush index ≥8N·m/g (moisture content 8-10%) | |

| Medium paper specification | 80-160g/㎡, ring crush index ≥5.5N·m/g (moisture content 8-10%) | |

| Flute combinations | A, C, B, E, F, G | |

| Power supply | AC380V 50Hz 3PH | |

| Installed capacity | Approx. 100kW | |

| Typical power consumption | Approx. 50kW | |

| Compressed air | Max. pressure | 8kg/cm² |

| Typical pressure | 5-7kg/cm² | |

| Consumption | 1m³/min | |

| Space requirement | Approx. Lmin40mxWmin10mxHmin5m (subject to drawings provided by the supplier and approved) | |