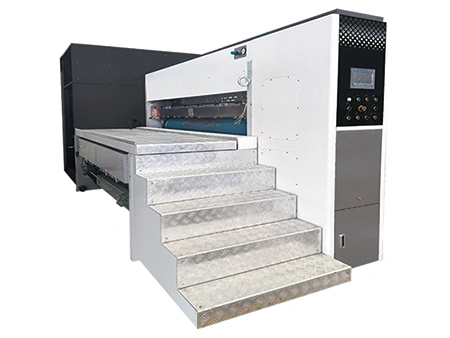

Flexo Printing Machine

(Servo Printer Flexo Printer Folder Gluer with Dual Printing Rolls)

Servo printer flexo printer folder gluer with dual printing rolls integrates printing, slotting, die-cutting, folding, gluing, and bundling into a fully automated production line. It is suitable for corrugated boxes, corrugated board, large paper products, newspapers, books, magazines, and packaged garments. The machine adopts mechanical or electronic control, delivers stable performance, features a robust structure, and is easy to maintain.

- Integrates printing, slotting, die-cutting, folding, gluing, and bundling into a complete one-pass converting solution. Eliminates multi-machine transfers, significantly reducing manual intervention, handling loss, and overall production costs.

- Each section is independently driven by Siemens servo motors for precise speed and motion control. This ensures perfect synchronization across all modules, achieving zero-error converting accuracy and reducing waste in printing, slotting, and die-cutting.

- The printer is equipped with two sets of printing rolls, allowing fast switching between printing plates. Job changeover requires only 2 minutes, greatly reducing downtime.

- A full Siemens electrical control system ensures stable performance, low failure rates, and high reliability during long-term, high-frequency operation.

- The printer supports reliable printing with multiple LPI options to meet various precision requirements.

Independent servo-driven feeding with vacuum front-edge suction using dual air chambers. Variable-frequency airflow adjustment provides stable and precise sheet feeding. Equipped with a servo feeding system, stable feeding system, and one-touch machine reset system for fast and convenient job changeover.

Left and right side guides, along with the rear paper stop, are computer-controlled and move smoothly through a precision guiding mechanism. A built-in side-tapping function helps keep sheets properly aligned.

Full-process vacuum-assisted feeding with inverter-controlled suction ensures stable sheet handling. The doctor blade system paired with a ceramic anilox roll delivers high-line, precision printing with consistent doctoring pressure. A pneumatic diaphragm pump provides reliable ink circulation and fast cleaning. Print cylinders feature horizontal and circumferential reference marks for easy registration and plate mounting. The unit supports quick replacement of doctor blades and anilox components and includes plate-cleaning memory with automatic reset. Dual printing rolls allow 2-minute plate changeovers for fast, efficient job switching.

The infrared drying system eliminates problems caused by insufficiently dried water-based inks, enhancing both print quality and coating performance. A pneumatically controlled lift mechanism allows the dryer chamber to rise quickly and adjust the drying width to match the board size, improving energy efficiency. Full vacuum-assisted sheet transport with variable suction ensures stable feeding, while adjustable air gates accommodate different board lengths. An optional UV curing system is also available.

Computer control and electric control buttons support fully automatic knife positioning and motorized fine adjustment. Equipped with self-locking pre-creasing quick adjustment mechanism and polyurethane creasing wheels to protect board surface hardness. Synchronous motorized axial movement combined with self-lubricating guide mechanism ensures precise and durable adjustment. Creasing and slotting shafts use high quality alloy steel with hard chrome plating and dual dynamic balancing. Slotting knives use 7 mm alloy steel. Additional components are available on request.

Fitted with imported quick-change polyurethane anvil blankets with linear speed compensation and correction to ensure consistent die-cutting and lower operating costs. The anvil cylinder features mechanical spiral shifting of ±20 mm to prolong anvil blanket service life. The gap between the anvil roll and the die roll is pneumatically controlled. A waste-removal conveyor at the base efficiently clears debris.

Automatic adjustment through computer control after inputting size specifications. Air blowing device clears slotting debris and imported conveyor belts ensure smooth transport.

Equipped with an easy-maintenance gluing system, the section adopts CNC linkage control that integrates the HMI, Siemens control, and servo drive. Servo differential adjustment, suction-belt transport, and servo-driven left and right re-creasing units ensure precise folding. High-strength folding arms combined with a precision lateral guiding system further enhance overall stability.

The section features computer-controlled counting and drop-type servo stacking for smooth, reliable collection. A pneumatic stacking mechanism keeps boxes neatly aligned, while the automatic squaring system extends correction time to ensure strong, secure bonding.

| Max. sheet pass size, mm | 900x2000 / 1200x2500 / 1400x2500 / 1600x2900, etc. (customizable) |

| Design speed, pcs/min | 200 / 300 |

| Feeding unit | Light-pressure, pressure-free (Siemens servo motor driven) |

| Printing unit | 1-6 colors (optional ceramic anilox doctor blade) |

| Slotter unit | Computer-controlled |

| Die cutting unit | Servo control (Siemens) |

| Folder gluer unit | Glue spraying system |

| Bundling unit | PP (polypropylene) or PE (polyethylene) |