Semi-Automatic Flatbed Die-Cutter

Flatbed die-cutting and creasing machine with stripping station for corrugated board converting

Request a Quote

Structure

Stripping Station

Stripping Station

Die-Cutter

Die-Cutter

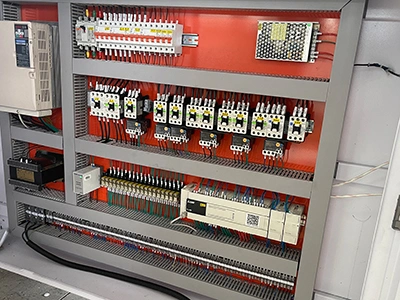

Electrical Cabinet

Electrical Cabinet

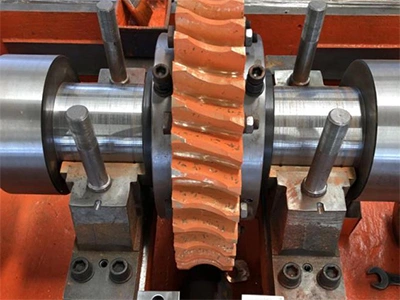

Chain Drive and Conveyor Section

Chain Drive and Conveyor Section

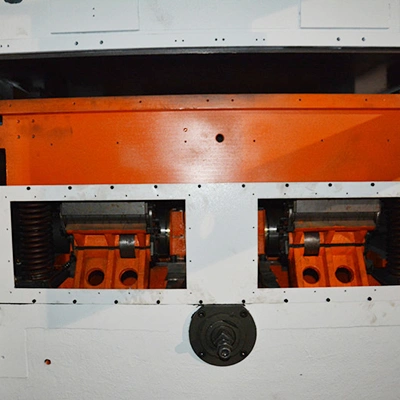

Die-Cutting Station

Die-Cutting Station

Motor

Motor

Main Components

Feeding and Output Section

- Maximum stack height: up to 1400 mm at the feeder and up to 1250 mm at the delivery.

- A center-mounted display screen allows operators to easily monitor rear-side operations.

- The pre-stacked system and specially designed pneumatic lift table greatly reduce setup time.

- A non-stop sampling system enables board inspection while the equipment remains in operation.

Main Unit

- Equipped with an automatic centralized lubrication system, with main-chain lubrication controlled through the HMI.

- The patented shock-absorption system extends the machine’s service life and increases cutting pressure.

- An intermittent gearbox ensures precise registration and reduces impact on the gripper bar system.

Die-Cutting and Conveying System

- The die-cut chase is locked in place by a pneumatic clamping system for accurate positioning.

- The cutting plate slides in and out on an air-float system for easy handling.

- An electric-powered clutch stabilizes the chain during emergency stops at high speed.

- Main and auxiliary chains receive scheduled lubrication controlled via PLC.

- A protective cutting station window helps keep the interior clean.

- The machine uses a lightweight and durable five-piece aluminum gripper bar system, paired with Renold (UK) or IWIS (Germany) chains, ensuring precise and reliable sheet transport.

Technical Specifications

| Model | | | | |

| Max. paper size, mm | 1320x980 | 1510x1120 | 1670x1200 | 2100x1600 |

| Min. paper size, mm | 350x450 | 450x500 | 500x550 | 600x600 |

| Max. die cutting size, mm | 1300x960 | 1490x1100 | 1650x1180 | 2050x1550 |

| Min. gripper edge size, mm | 8 | 8 | 8 | 10 |

| Max. die cutting pressure, N/cm² | 350 | 380² | 400 | 500 |

| Processable paper-cardboard, g/m² | 200-2000 | 200-2000 | 200-2000 | 200-2000 |

| Processable paper-corrugated board, mm | 10 (max. thickness) | 10 (max. thickness) | 10 (max. thickness) | 10 (max. thickness) |

| Max. die cutting speed, sheets/h | 5000 | 5000 | 4200 | 3800 |

| Max. feeding pile height, mm | 1400 (above floor level) | 1400 (above floor level) | 1400 (above floor level) | 1400 (above floor level) |

| Max. collecting pile height, mm | 1250 (above floor level) | 1250 (above floor level) | 1300 (above floor level) | 1300 (above floor level) |

| Total power, kW | 15 | 15 | 20 | 25 |

| Machine weight, T | 14.5 | 17 | 21 | 30 |

| Machine dimensions (LxWxH), mm | 4200x4250x2250 | 4500x4300x2250 | 5200x4950x2250 | 6500x5050x2400 |