Automatic Folder Gluer

Fully automatic folding and gluing machines for making corrugated boxes

The automatic folder gluer consists of three main sections: vacuum feeder, gluing and folding unit, and counter and stacking unit.

All motors, except the variable-frequency motor, are Shengbang (Taiwan) units. The automatic folder gluer uses variable-frequency speed control and standard dual PLC touchscreen operation. Fully motorized adjustment allows the equipment to automatically set to the correct dimensions by simply entering length, width, and height on the touchscreen. This ensures simple, reliable operation, with a maximum carton speed of 180 m/min and an average speed of 150 m/min, delivering high-speed, energy-efficient performance while reducing labor costs.

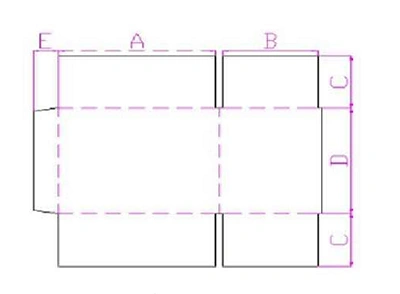

| Model | QH1226 |

| Max. size (A+B)x2, mm | 2600 |

| Min. size (A+B)x2, mm | 420 |

| Max. A, mm | 900 |

| Min. A, mm | 130 |

| Max. B, mm | 650 |

| Min. B, mm | 80 |

| Max. size (C+D+C), mm | 1200 |

| Min. size (C+D+C), mm | 170 |

| Max. C, mm | 430 |

| Min. C, mm | 50 |

| Min. D, mm | 100 |

| Max. D, mm | 700 |

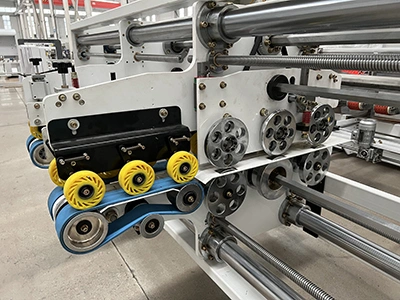

The vacuum feeder provides improved adaptability for boards, while variable-frequency control allows independent adjustment. Corrosion-resistant and wear-resistant stainless-steel glue rollers ensure uniform glue application and reduce glue consumption to approximately one-third of manual application.

Imported wear-resistant rubber belts convey boards for extended service life. Features board alignment and crease rollers adjustable for 2-8 mm thick boards. A secondary creasing mechanism allows reprocessing of boards with poor initial crease quality.

Motorized lateral movement ensures stable output of large cartons. Robotic design provides stable stacking of small boards. Calibration guides allow one-touch sequence switching and automatic adjustment, with adjustable deviation correction. Counting output uses pneumatic operation for precise and rapid performance.