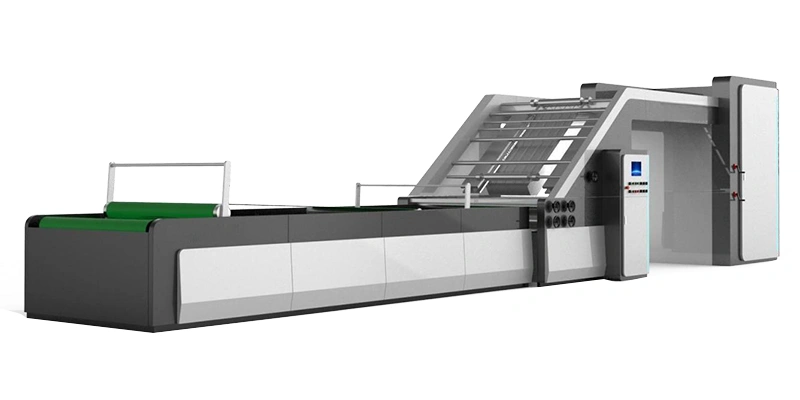

Automatic Flute Laminating Machine (15,000 sheets/hour)

Request a Quote

Structure

Lead-Edge Feeder

Lead-Edge Feeder

Sheet Feeding Section

Sheet Feeding Section

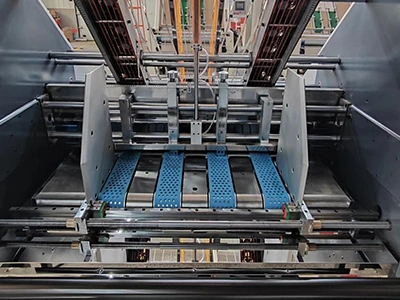

Belt Lead-Edge Section

Belt Lead-Edge Section

Laminating Section

Laminating Section

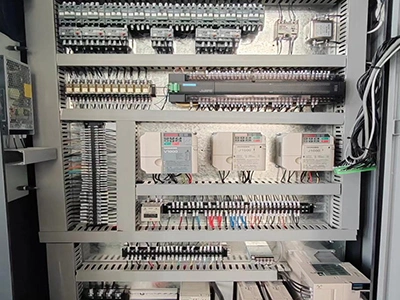

Electrical Cabinet

Electrical Cabinet

Laminating Section

Laminating Section

Features

- Computer-controlled operation: All operating data are displayed on the microcomputer interface, improving efficiency, reducing operator workload, and enhancing product quality control.

- High laminating speed: Computer-controlled lamination enables output of up to 15000 sheets per hour when sheet width is within 700 mm.

- Precision alignment and bonding: Multiple photoelectric sensors monitor the relative position between top sheet and bottom sheet. Independent servo motors on both sides of the top sheet provide compensation, achieving bonding accuracy within ±1.0 mm for smooth and precise operation.

- Stable glue control: High-precision coating and conveying system with automatic liquid-level control ensures clean operation at high speed without glue overflow. Adjustable glue return system reduces glue waste.

- Smart electrical control system: HMI plus PLC with indicator status display provides automatic job monitoring, fault display, and job recording. Electrical protection meets CE standards.

- Precision structural machining: Main side frames are processed on machining centers to eliminate assembly errors. Protective covers are CNC-manufactured for a clean appearance and solid structural integrity.

- Optimized sheet conveying: Bottom sheet feeding uses servo control with wide conveyor belts for accurate delivery and registration. Top sheet conveying uses PU round belts with lower suction fan and servo-driven feeder, ensuring smooth, stable transport.

- Durable exterior finish: Protective covers feature electrostatic powder coating, providing clean appearance that enhances overall machine quality.

Configurations

| Configuration category | Brand / model |

| Main motor | Siemens |

| Critical bearings | SKF (over 90% of the machine) |

| Electrical control components | PLC program control; Omron (VFD speed control / photoelectric sensors); Schneider (push buttons) |

| Transmission system | Gates synchronous belt |

| Coating roller | High-precision mirror-finish roller |

Technical Specifications

| Machine model | | |

| Max. paper size, mm | 1450x1450 | 1700x1450 |

| Min. paper size, mm | 400x380 | 400x380 |

| Surface paper thickness, g/m² | 200-800 | 200-800 |

| Bottom paper thickness, mm | 0.5-12 | 0.5-12 |

| Machine speed, m/min | 176 | 176 |

| Laminating precision, mm/m | ±1 | ±1 |

| Machine dimensions (LxWxH), mm | 14000x2500x2400 | 14000x2700x2400 |

| Machine power, kW | 25 | 28 |

| Machine weight, t | 7.2 | 7.8 |