Automatic Flatbed Die-Cutter

Flatbed die-cutting and creasing machine with stripping station for corrugated board converting

Request a Quote

Structure

Delivery Unit

Delivery Unit

Staking Section

Staking Section

Stripping Station

Stripping Station

Die-Cutter

Die-Cutter

Screen Control

Screen Control

Feeder

Feeder

Lead-Edge Feeder

Lead-Edge Feeder

Electrical Cabinet

Electrical Cabinet

Electrical Cabinet

Electrical Cabinet

Main Components

Lead-Edge Feeder

- The front plate can be adjusted up or down according to board thickness.

- Equipped with a high-pressure blower with independently adjustable inverter-controlled air volume.

- The upgraded lead-edge feeder delivers more accurate feeding, significantly improving board adaptability.

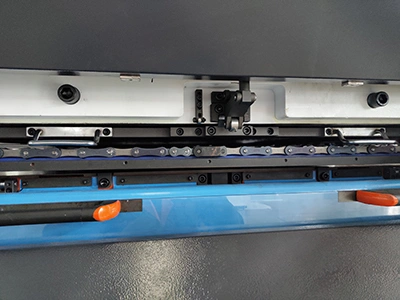

Die-Cutter

Uses a crank-driven platen die-cutting and creasing. The precision worm gear with synchronous belt drive ensures stable motion.

Equipped with:- High-torque pneumatic clutch/brake

- Multicam intermittent indexing mechanism from renowned brands

- Reliable torque limiter (protecting the INDEX system)

- Inclined-pressure micro-adjustment device (+1.5 mm total adjustment range)

- Durable pre-stretched gripper bar drive chain

These elements ensure accurate and consistent die-cutting performance.

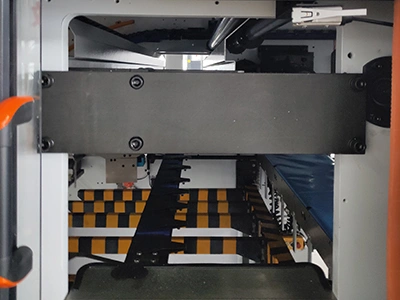

Stripping Station

- Both upper and lower frames use a linkage-type stripping mechanism for stable and precise operation.

- The stripping plates improve accuracy, and the central positioning system allows faster plate changes, saving setup time.

- The upper frame features electric lifting.

Delivery Unit

- A roller-support lifting platform prevents scratching on the sheet surface during delivery.

- Supports quick output of full piles or counted batches.

- The adjustable tension spring chain cushions the idler wheel, greatly reducing the inertial impact during gripper bar reversal and maintaining balanced chain tension.

Electric System

- Designed with CE-standard dual safety door protection.

- Main components are sourced from established brands such as Siemens, Yaskawa, Schneider, Omron, Mitsubishi, Pizzato, ensuring reliable and stable system performance.

Technical Specifications

| Model | 1650 |

| Die cutting style | Flat-to-flat |

| Max. paper size, mm | 1650x1200 |

| Min. paper size, mm | 650x500 |

| Max. die cutting size, mm | 1630x1180 |

| Max. die cutting pressure, T | 450 |

| Processable cardboard thickness, mm | 0.7-9 |

| Waste paper edge, mm | Min. 10 |

| Max. die cutting speed, sheets/h | 5000 |

| Gripper edge, mm | Min. 6 |

| Power, kW | 35 |

| Gross weight, T | 38-40 |

| Machine weight, T | 14.5 |

| Machine dimensions (LxWxH), mm | 4200x4250x2250 |